- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2024-06-20 Origin: Site

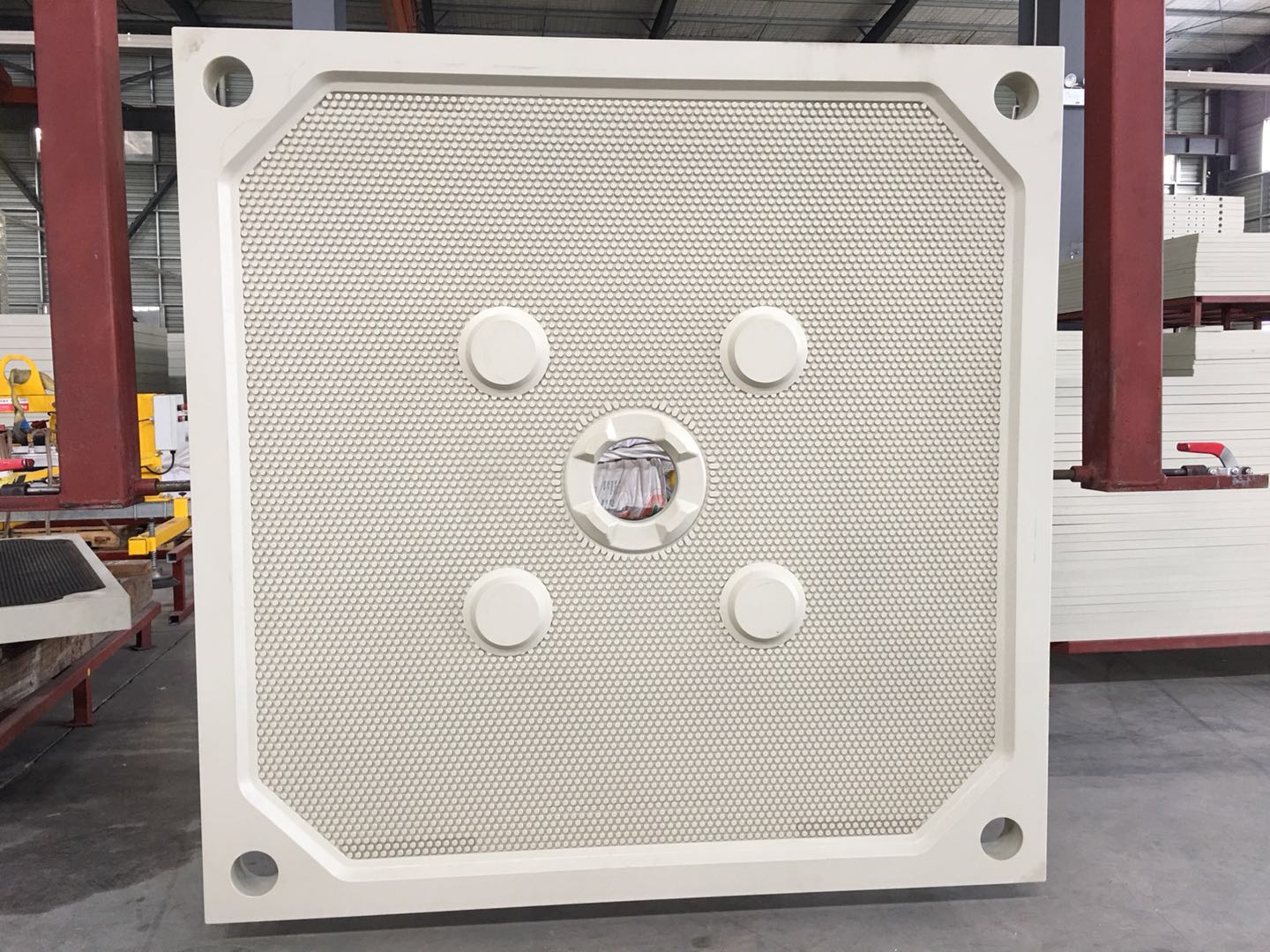

In modern industry, filter presses are common and important equipment widely used in mining, chemical, pharmaceutical, food, and wastewater treatment industries. By using physical separation, filter presses separate solids from liquids in solid-liquid mixtures. As one of the core components of the filter press, the chamber filter plate plays a crucial role in the entire filtration process.

Structure and Function of Chamber Filter Plates

The chamber filter plate is the main filtering element in a filter press, typically made of reinforced polypropylene or other corrosion-resistant materials. Its design features a hollow chamber form, with filter cloth on both sides. When the hydraulic system is activated, the solid-liquid mixture is pressed into the chamber of the filter plate. As the pressure increases, the liquid passes through the filter cloth and small holes in the filter plate, while the solids are retained on the filter cloth, forming a filter cake.

1. Efficient Filtration: The design of chamber filter plates can withstand higher pressures, making the solid-liquid separation process more thorough and significantly improving filtration efficiency and capacity.

2. Strong Corrosion Resistance: Chamber filter plates are often made of reinforced polypropylene and other corrosion-resistant materials, making them suitable for various acidic and alkaline environments, thus extending their lifespan.

3. Ease of Cleaning: The flat surface design of chamber filter plates facilitates easy cleaning and maintenance, reducing downtime and increasing production efficiency.

Application Cases

1. Mining Industry: In the mining industry, filter presses and chamber filter plates are used for mineral concentration and tailings treatment. The high-efficiency solid-liquid separation capability helps improve mineral recovery rates while reducing wastewater discharge and environmental pollution.

2. Chemical Industry: The chemical industry processes large amounts of chemical mixtures. Filter presses and chamber filter plates efficiently separate solids from liquids, enhancing product purity and quality.

3. Pharmaceutical and Food Industries: In the pharmaceutical and food industries, filter presses are used in production processes to ensure that products meet hygiene standards.

4. Wastewater Treatment: In wastewater treatment plants, filter presses and chamber filter plates are used for sludge dewatering, effectively reducing sludge volume and lowering treatment costs.

Future Development Trends

With increasingly stringent environmental regulations and the emphasis on resource recovery and utilization, the demand for filter presses and their core components, such as chamber filter plates, will continue to grow. Future development trends will focus on:

1. Automation and Intelligence: By introducing automated control systems and intelligent monitoring equipment, the operational efficiency and fault warning capabilities of filter presses can be improved, reducing the need for manual intervention.

2. Material Innovation: Developing more durable and environmentally friendly filter plate materials to meet more demanding working environments and higher filtration requirements.

3. Energy Saving and Consumption Reduction: By optimizing the structural design and operating parameters of filter presses, energy consumption can be reduced, enhancing economic benefits.

Conclusion

As the core component of a filter press, the performance of the chamber filter plate directly impacts the filtration efficiency and service life of the entire equipment. In various industrial fields, chamber filter plates, with their efficient, durable, and easy-to-maintain characteristics, have become indispensable in solid-liquid separation processes. With continuous technological advancements and increasing application demands, chamber filter plates will play an even more important role in future industrial production.